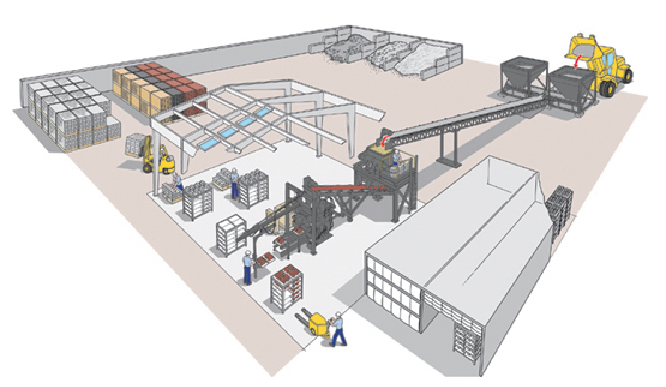

(Medium Production Operation)

Existing Producers that generally need a block and paving stone machine that is automatic but still offers less material handling automation in the early stages of business. The design of a Level 3 plant allows the producer to add on equipment as the business grows to eliminate labor and gain production efficiencies. They tend to know the amount of concrete production required on a daily level and have sales to obtain that goal. Buyers are normally privately owned businesses that are interested in making a high quality unit without a huge degree of concrete block making automation to maintain a simple and affordable investment.

At this level, producers are often willing to integrate and combine the package with both reconditioned equipment and new equipment to keep the overall investment affordable. Oftentimes, they need help in finding proper financing in addition to obtaining the correct qualified people to perform the operation.

Erosion control blocks are a flexible, interlocking matrix of concrete blocks with uniform size shape, and weight used for erosion coastal ocean areas and erosion control inner channels. All units can be made on our block machines with or without core pullers in a normal thickness of 4”- 8” (10 x 20 CM).

Level 3 production plants include a concrete batch mixer that would be charged with sand, rock, water and cement. Each batch is automatically weighed to formulate the correct formulated mix for accuracy. Cement is normally stored in a bulk storage tank and also weighed to a predetermined amount and then conveyed into the concrete mixer. All the ingredients are mixed and the water added automatically to create the perfect mix in moisture content and consistency. Once the concrete is ready it is then discharged and conveyed or transported by skip bucket to the block machine. The concrete block machine will produce up to the below listed output levels per day.

| Products | Production in 8 Hours |

| 6″x8″x16″(15x20x40cm) | Up to 32,000 Concrete masonry units (CMU) per day |

| 8″x8″x16″(20x20x40cm) | Up to 10,200 Concrete masonry units (CMU) per day |

| Paving Stones | Up to 6544 sq.ft. per day (836 M2) |

Level 3 Block & Paving Stone Plant. Includes a loader fed Batch Plant with aggregate bins, automatic weigh batching, cement silo, auger, and weigh cement hopper. System uses planetary mixer and conveys the concrete mix to the fully automatic block. Machine then stacks units using automatic stacker device.

Level 3 Block & Paving Stone Machine. Is one of the most advanced machines on the market today with an extremely fast return on your investment. The block and specialty machine utilizes an extra heavy duty frame structure, variable speed vibration and operation speeds with an on-line internet service support system.

Use this link to get your answers by reading “The Only Block Machine Buyers Guide You’ll Ever Need.” If you don’t know the exact sizes and shapes of products, just pick up the phone and I can help you walk through the process. E-mail me anytime at billfleming@globalmachinemarket.com with your questions to get your answers.