Global Machine Market

When you’re considering a mixer for your operation, you need to make absolutely sure that you select the correct size. Otherwise, you’ll lose out on profits for years due to unnecessary slowdown in your operations.

Size, of course, is not the only consideration. You’ll also need to take into account material input and output times, while honing in on the right mixing time for your materials.

Another mistake producers can easily make is selecting the wrong type of mixer for their operations. Selecting the wrong mixer can significantly affect your bottom line.

That’s where Global Machine Market and planetary mixers come in. Planetary mixers use a special type of pan mixer to offer short mix times and vigorous mixing for quick and uniform batches.

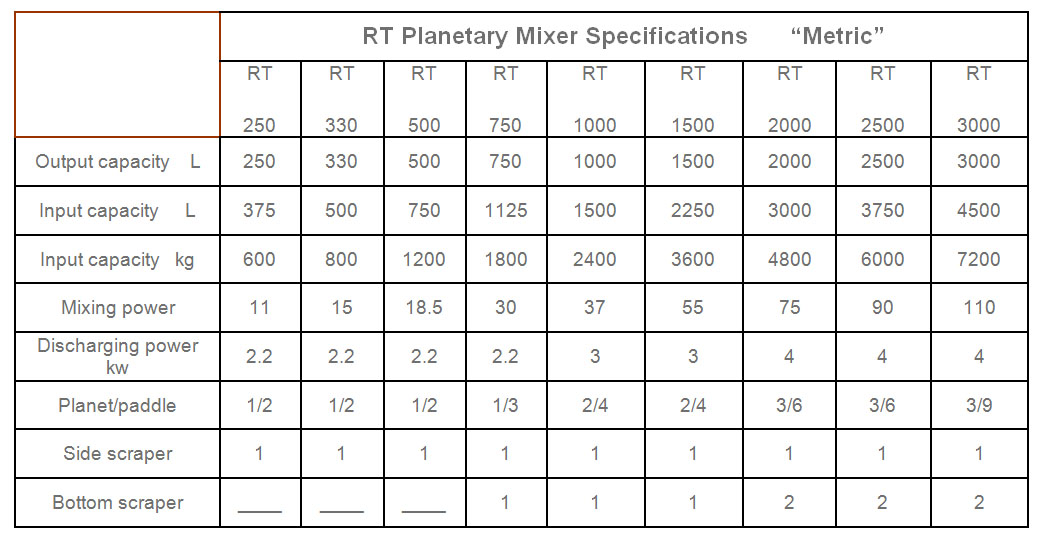

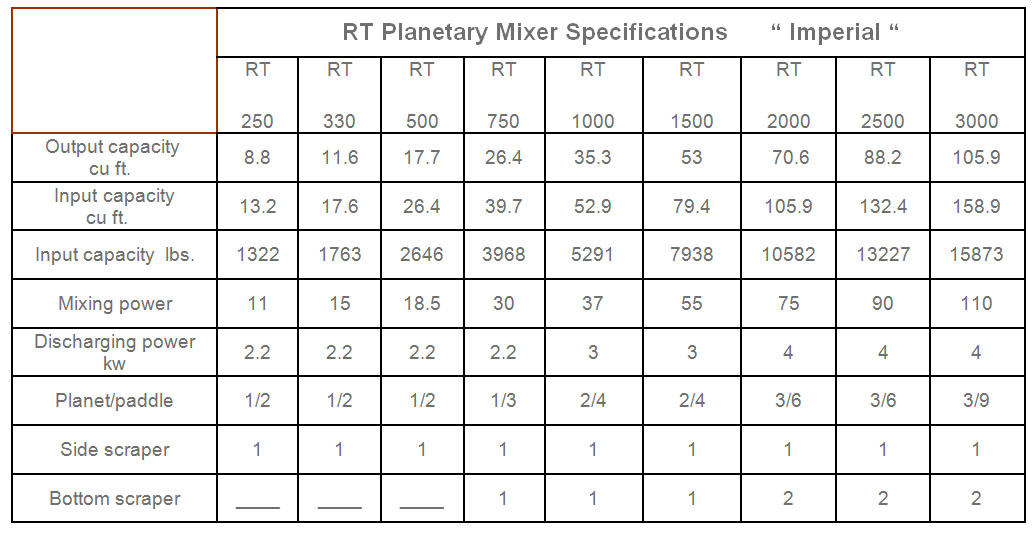

Our mixers come in different sizes, ranging from ½ cubic yards to 3 yards. They are often used in precast and product concrete plant applications. Planetary mixers use several mixing stars for unparalleled mixing action.

If you are ready to find the right size mixer for your needs, contact Global Machine Market with your questions and specifications. We’ll help you to explore your options and find the right solution for your needs and your budget.

How Do Planetary Mixers Work?

RT planetary concrete mixers are designed to produce concrete of extraordinary quality at high speeds. Every planetary mixer’s frame is constructed to be stronger than virtually any other type of mixer in the industry, granting them incredible dependability.

With such a strong and massive body frame, planetary mixers’ multi-star mixing action provides the fastest and most complete mixing of full-sized batches. As an added benefit, the intense mixing action that a planetary mixer offers will save you money on your cement costs.

Versatility is the key to running an efficient operation. With planetary mixers, you can work with high-density materials besides concrete, as well. This includes slag or steel fines, both of which are often double the weight per cubic foot of concrete.

In fact, planetary mixers are so powerful that they can start mixing with a full batch of materials, going from perfectly still to full-speed operation in seconds flat.

Each planetary mixer is equipped with extra heavy-duty door and shaft seals to prevent the leakage of materials. For simple and easy cleaning, access hatches open wide to provide full access for maintenance.

This is an essential feature for any operation that produces several colored mixes in a single day, allowing you to clean before mixing the next batch. This will save you a great deal of time, money, and material.

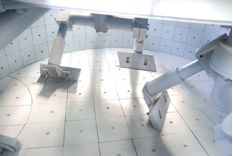

Planetary mixers use one to three mixing stars, depending on the size of the mixer that you need. Each star is rotated around a central shaft, and each star rotates individually. This design allows each arm or star to move around the entirety of the mixing chamber.

Because of the sheer intensity of this mixing action, you can expect a mixing cycle time of about 30 seconds for most types of concrete after the last drops of water are added to the mix. This lets you mix more concrete per hour, boosting production and allowing your business to grow as quickly as you need.

Not only that, but you’ll start to notice savings on cement costs. Considering how costly cement can be, you can rely on planetary mixers to widen your profit margins to a more comfortable size.

Here are some of the other benefits of planetary concrete mixer machines:

Incredible Performance

During the mixing process, the material inside your mixer is affected by both cyclic motion and convective movement. Mixing action is more intense with our machines, and mixing power is significantly stronger than other types of mixers.

Concrete Mixing Producers:

RT Planetary Mixers produce extraordinary quality concrete at high speeds with outstanding dependability.

“Which equipment will make the best quality mix and provide you with the most profits?

Concrete Batch Mixing and Batch Plant Owners:

“Boggled about what size and type concrete mixer you need for your operation”?

One of the biggest mistakes you can make is choosing a concrete batching mixer is not choosing the correct size output production for your needs.

If you don’t size the mixer properly it will cost you money and lost profits for years in slowing down your operation. There are many considerations such as material input and output times along with what is the proper amount of mixing time of your materials. Ready to determine which size is right for you? Email me with your questions and I’ll walk you through it. The next most common mistake is producers choosing the wrong type of mixer for their application. It can be costly to your bottom line unless you understand the types which are best for you.

__________________________________________________________________________

Planetary Mixer / Countercurrent

You should be looking at a planetary mixer if your requirements are to make high quality precast and primarily interlocking pavers, building blocks (CMU) architectural blocks in a fast manner with great consistency.

Production of the following products:

Concrete building blocks

Concrete bricks

Concrete Pipes

Powder blending

(e.g. glass and ceramics)

Grouts and screeds

Pre-cast concrete

SCC Products

Steel Briquettes

Refractory Products

Architectural Concrete Blocks

Washing machine counter weights

Segmental retaining wall blocks

Air conditioner pads

Patio Slabs

Calcium – Silicate bricks

Pre-stressed concrete

Light weight concrete products

Colored and multi-colored bricks

Concrete Roof Tiles

Ready mixed concrete

Clay bricks

Statuary figured

Mortarless Building Blocks

Foundation Blocks

Concrete Fence Blocks

Wood Building Blocks

Concrete erosion control blocks

Splash blocks

Highway concrete sound panels

Ready to learn more? Just send me an e-mail with the amount of material you want to mix per hour or per day. Click on to Questions about concrete mixers or pick up the phone and call me at 314-960-0540. I will get back in contact with you within 48 hours with a response.

RT Planetary Mixers

Producers who have planetary mixers are generally looking to mix materials in a fast manner and utilize up to four material discharge gates for color segregation using multiple hoppers. You would like the aspect of being able to easily clean the inside of the mixer with its totally open floor design.

Dual Planetary Mixers – Six Aggregate Bins – Two Cement Silos – Low Profile Weigh Belt Batch Plant.

The RT planetary concrete mixers are designed to produce extraordinary quality concrete at high speeds with outstanding dependability. The massive body frame of the mixer is built stronger than most any other mixer in the industry. This ensures that it’s multi-star compulsory mixing planetary mixing action gives the fastest and most complete mixing of full size batches. Because of the intense mixing action you the producer can actually save cement cost.

Our mixers are able to work with very high density materials outside the concrete market such of slag or steel fines for mixing which are often double the weight per cu. ft. of concrete material. The mixer is so powerful it has started with a full batch of material in a still position to fully operating speed in a material of seconds.

The unit is equipped with extra heavy duty door and shaft seals to prevent any material leakage. Cleaning is also very simple with full access covers that open wide so maintenance and dialing cleaning can be performed. This is also important when you are producing several different colored mixes in one day obtaining a thorough clean for next color. Saves the producer time, money and material.

In the planetary mixer or as the industry also often referred to as countercurrent the design uses one to three mixing stars, depending on the size mixer you choose. Each star rotates individually while also rotating around a central point, allowing each arm to travel around the entire mixer floor area. The intenseness of the mixing action is fast and comprehensive, ensuing a mixing cycle time down to 30 seconds for most types of concrete after the final water is added to the mix. That is more concrete per hour so you can make more profit and grow your business faster. If you are like many users in the industry you will start to see cement savings. With cement being a major cost in the mix that will be a huge factor to the profit each day.

Planetary concrete mixers allow producers to make a consistent mix that has a fast mixing and discharge time.

To understand why the planetary has such a good blending action compared to other types of mixers? Click on the below link below and I will explain the details to you. https://screencast.com/t/OnUXqCfx

Planetary Concrete Mixers Producers for Sale USA

If you are looking for a planetary concrete mixer machine for sale to improve your operations, Global Machine Market can help.

With our affordable pricing and high-quality equipment, you won’t need to search the dark corners of the internet for “planetary concrete mixers producers for sale USA” anymore. We offer the best planetary concrete mixer machine for sale in the country, so that you can take your operation to the next level.

When you partner with the team at Global Machine Market, you can rely on our 80+ years of industry experience and shining reputation to guide you to the best equipment for your operation. If you want to grow your business, we can show you what you need to do to make it happen. Give us a call today!

RT Main Concrete Mixer Features include:

Homogeneous consistent top quality concrete

Fast pigment dispersion

Forced action fast mixing time

Robust, heavy duty and hard wearing

Fast discharge time

Door position flexibility

Low maintenance costs

High quality low cost wear parts

High quality low cost wear parts

Minimum maintenance

Safety Mixer Door Interlocks & multiple Door access for easy cleaning.

Maximum access for easy cleaning

Low profile design

Wall and floor of the planetary mixers are lined with long lasting wear resistant bolt-in replaceable wear parts.

The wall and floor of the mixer are lined with long lasting wear resistant bolt in replaceable wear parts

Planetary Mixers are used for the production of the following products:

Concrete blocks

Concrete bricks

Pipes

Powder blending

(e.g. glass and ceramics)

Grouts and screeds

Interlocking paving

Pre-cast concrete

Calcium – Silicate bricks

Pre-stressed concrete

Light weight concrete

Colored and multi-colored bricks

Roof Tiles

Ready mixed concrete

Clay bricks

Planetary Mixers

When you’re considering a mixer for your operation, you need to make sure that you select the correct size and type. Otherwise, you’ll lose out on profits for years as you face unnecessary slowdowns in your operations.

Size, of course, is not the only consideration. You’ll also need to take into account material input and output times while honing in on the right mixing time for your materials.

Another mistake producers can easily make involves selecting the wrong type of mixer for their operations. Choosing the incorrect mixer, like a spiral blade mixer instead of something more powerful, can significantly affect your bottom line.

That’s where Global Machine Market and our planetary mixers come in. Planetary mixers use a special type of pan mixer to offer short mix times and vigorous mixing for quick and uniform batches ready to be stored in your concrete mixer silos.

Our mixers come in different sizes, ranging from ½ cubic yard to 3 yards. They are often used in precast and product concrete plant applications. Planetary mixers use several mixing stars for unparalleled mixing action.

If you are ready to find the right size mixer for your needs, contact Global Machine Market with your questions and specifications. We’ll help you explore your options and find the right solution for your needs and budget. With our assistance, you can optimize your mixing operations in no time.